Piping systems are rarely static. As temperatures fluctuate and operating conditions change, pipes expand, contract, and shift, and sometimes more than designers expect. When movement is unavoidable, controlling it properly becomes critical. That’s where low friction guides and anchors can really help.

So when should you consider using them? Let’s break it down.

When Thermal Movement Can’t Be Ignored

If your piping system operates at elevated temperatures, thermal expansion is a guarantee. As pipe grows and shrinks, resistance at support points can introduce stress, misalignment, or even damage to connected equipment.

Low friction guides are ideal when axial movement needs to be allowed without transferring excessive loads into the pipe or structure. By reducing resistance between sliding surfaces, these supports help piping move as designed instead of fighting against it. In systems where predictable, controlled movement is essential, low friction pipe support solutions can significantly extend service life and reduce maintenance headaches.

When You Need Control

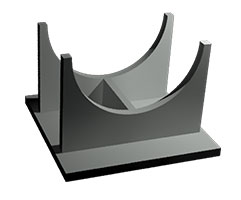

Guides and anchors serve different purposes, but together they create order in a dynamic system. Guides allow movement in specific directions while restraining others. Anchors, on the other hand, lock the pipe in place to establish fixed points and direct expansion where you want it to go.

Low friction designs shine when movement must be carefully managed over long distances or where lateral and axial displacement are both factors. For example, piping that runs between major pieces of equipment or across pipe racks benefits from supports that allow smooth motion without binding. In these cases, engineered pipe guides and anchors help maintain alignment while preventing unwanted stress buildup.

When Operating Conditions Are Demanding

Not all environments are forgiving. High temperatures, heavy loads, and long-term operation require materials that won’t degrade or seize over time. Low friction graphite surfaces are particularly effective in harsh conditions, offering consistent performance under pressure and heat.

If your system operates at temperatures approaching 750°F, or if long-term reliability is a top priority, it’s worth considering solutions specifically designed for those extremes. Custom configurations can also accommodate larger pipe sizes, thicker insulation, or greater-than-normal movement. This is where collaboration with experienced piping support engineers becomes invaluable.

Ultimately, low friction guides and anchors are about confidence that your piping system will move the way it’s supposed to, without surprises. They reduce wear, minimize maintenance, and help protect the entire system over its lifetime.

To learn more about the benefits of low friction guides and anchors, contact us.

Recent Comments