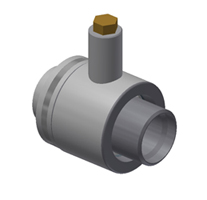

Industrial ball joints may be small components, but they play an outsized role in ensuring safe, efficient, and reliable movement within piping systems. Regardless of your application needs, choosing the right ball joint is essential. Below, we break down what to look for so you can choose confidently and keep your system performing at its best.

Understand Your Application Requirements

Before selecting any industrial ball joint, start by identifying the specific demands of your application. Are you working with high-temperature service? Do you need to accommodate large angular movement? Will the joint need to handle corrosive media or withstand high cycle frequencies?

Each of these variables influences the best material choice, joint design, and packing method. For example, specialized metal alloys may be required for extreme temperatures, while chemically resistant components are better suited for corrosive environments. When in doubt, choose a solution that not only meets your current needs but offers a margin of safety for operational fluctuations.

Evaluate Design, Durability & Maintenance Expectations

A high-quality industrial ball joint should provide smooth delivery while minimizing leakage and wear. Look for features such as:

- Precision-machined sealing surfaces

- Replaceable or serviceable packing systems

- Rugged housing materials for long-term durability

It’s also wise to consider how accessible the joint is for inspection and maintenance. In systems where downtime is costly, joints designed for quick serviceability can provide a major operational advantage.

If your application involves piping movement in multiple axes, consider whether a double ball joint assembly or fully packed slip expansion joint may be a better overall fit. These options can manage additional movement without putting excessive strain on your equipment.

Choose a Manufacturer You Can Trust

Industrial ball joints are only as reliable as the team behind them. A manufacturer with decades of experience can provide not only high-quality components but also design guidance, customization options, and dependable support over the life of the product.

Look for a supplier who offers:

- Engineering assistance for custom applications

- Proven product testing and quality standards

- A range of complementary expansion joint solutions

By understanding your application, evaluating design considerations, and partnering with a trusted manufacturer, you can ensure long-term performance and safety in even the most demanding systems. If you’re ready to explore reliable, well-engineered solutions, contact Advanced Thermal Systems today.

Recent Comments