In any industrial piping system, flexibility and reliability are everything. For instance, when dealing with high temperatures, pressure changes, or complex layouts, even the smallest component can make a big difference in performance.

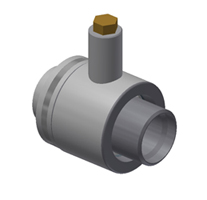

One such component is ball joint systems. These connectors allow movement, reduce stress, and keep your piping system running smoothly under the most demanding conditions.

What Makes Ball Joints So Effective?

Ball joint systems are designed to absorb angular and rotational movement in piping systems. Instead of allowing stress to build up at connection points (which can lead to cracks, leaks, or fatigue over time), ball joints provide freedom of motion that protects your entire network.

Whether your application involves thermal expansion, vibration, or system misalignment, ball joints provide an efficient solution. They’re especially beneficial in systems where space is limited or where movement occurs in multiple directions. Thanks to their compact design and ability to handle both hot and cold applications, ball joints help maintain structural integrity while minimizing maintenance needs.

Designed for Performance and Longevity

Notably, our ball joints are engineered to provide leak-proof performance and low-friction movement even in the harshest environments. Each joint is crafted with precision to ensure a tight seal and long-lasting performance, meaning fewer shutdowns and lower operational costs.

When used in combination with packed slip type expansion joints, low friction pipe supports, and pipe guides & anchors, ball joints contribute to a complete, balanced system that can adapt to thermal changes and mechanical stresses with ease. Together, these components form a reliable network that protects your equipment and extends the life of your system.

To learn more about precision-engineered ball joints or explore other advanced piping solutions, contact Advanced Thermal Systems today.

Recent Comments